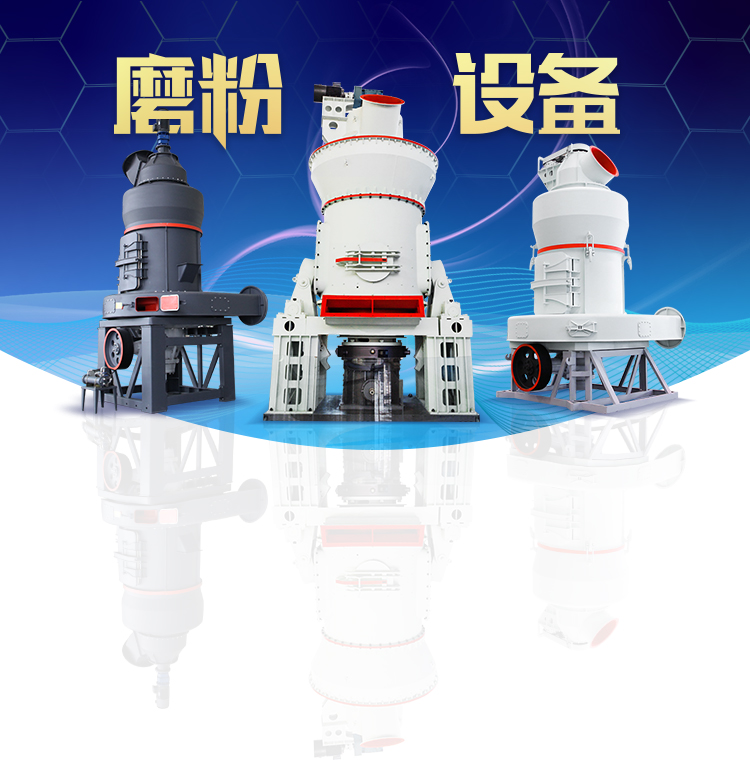

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Working Princle Of Coal Handling Plant Ball Mill

Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

The main Function of the Pulveriser in thermal power plant is to crush/grinding the raw coal coming from coal handling systemthrough coal feeder into a predetermined size in order to increase the surface area of the coal If the coal is not pulverised, the coal might not burn completely, thus 展开2016年8月1日 A duplex inlet and outlet ball mill pulverize system model is established by considering the effect of raw coal moisture on the dynamic characteristic of the mill The EKF Modeling and control of ball mill system considering coal moistureWorking principle Double inlet outlet ball mill has two symmetric circuits shown in picture Coal feeder sends coal into drop pipe Coal falls down to screw conveyor and gets pushed into cylinder of ball mill Inside, steel balls will Double inlet outlet ball mill Geckointech2014年4月1日 Adding biomass to coal for cofired power generation has become widely implemented practices in order to meet the emission regulation targets These have impacted A new modelbased approach for power plant Tubeball mill

.jpg)

Bowl Mill Coal Pulverizer COAL HANDLING

2023年12月14日 Coal Pulverizer are designed to reduce the size of the incoming raw coal to a fineness that will result in good furnace performance The grinding surface in the pulverizer resembles a shallow dish or bowl 2021年4月30日 In this mill the coal passes between the rotating elements again and again until it has been pulverized to desired degree of fineness The coal is crushed between two moving Ball And Race Mills Rama UniversityFind the Right and the Top Coal handling coal mill safety for your coal handling plant! liming, a mining machines manufacturer in china focus on your local solutions working principle of Mills In Coal Handling Plant2016年8月1日 A duplex inlet and outlet ball mill pulverize system model is established by considering the effect of raw coal moisture on the dynamic characteristic of the mill The EKF Modeling and control of ball mill system considering coal moisture

.jpg)

Flue Gas Desulfurization (FGD)

2021年4月11日 The reagent preparation system of flue gas desulfurization (FGD) includes a Wet ball mill and cyclone classifiers which produce a finely ground limestone slurry at Ball Mill Working Principle Center drive and side drive are two common drive modes for a ball mill Center drive grinding mill means the motor shaft extends along the axis of mill body while side working principle of ball mill in thermal poewr plant2015年4月24日 2 Ball mill consist of a hollow cylindrical shell rotating about its axis Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Ball mill PPT SlideShareThe most used coal mills in cement plants are airswept ball mills and vertical roller mills At present, most cement plants use coal as the main fuel in the clinker production process The standard coal consumed by the new dry Coal Mill in Cement Plant Vertical Roller Mill

.jpg)

An investigation of performance

2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical Years of cement production practice shows that cement particle gradation should be distributed continuously within a certain size range Generally speaking, the cement particles smaller than 32 μm are beneficial to reduce Ball Mill In Cement Plant Cement Ball Mill2020年1月1日 According to data from the World Coal Association, coalfueled power plants currently provide 37% of the global electricity [1] In 2017, China's coalfired power generation Wet and dry grinding of coal in a laboratoryscale ball mill: Particle Download scientific diagram Working process of a Tubeball mill from publication: A new modelbased approach for power plant Tubeball mill condition monitoring and fault detection With the Working process of a Tubeball mill

.jpg)

OPERATION AND MAINTENANCE OF CRUSHER HOUSE

2015年4月10日 power plants maximum requirements of fuel is a coal The handling of this fuel is a great job To handle the fuel, ie, coal, each power station is equipped with a coal handling Write better code with AI Code review Manage code changessbm/sbm working principle of coal handling plant ball mill2024年1月28日 2 Liners: An abrasionresistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding action 3 Balls: They place steel or ceramic Ball mill: Principles, construction, working, uses, 2025年1月8日 The four most common coal pulverizers types are: BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls Coal is introduced through two hollow trunnions on each side of the tube As the Coal Pulverizer – Power Plant Pall Corporation

Flue Gas Desulfurization (FGD)

2021年4月11日 One mill slurry tank and one slurry pump is supplied for one wet ball mill The mill slurry pump will send limestone to ball mill classifier to classify big size limestone 5 天之前 RingRoll (BowlMill) and BallRace Mills comprise most coal pulverizers currently in service at pulverized coal power plants The grinding rolls are stationary in this design, while a worm gear drive rotates the ring Coal Pulverizer – Power Plant Pall CorporationThe working principle of a ball mill is based on the impact and attrition between the balls and the grinding media As the mill rotates, the grinding media (usually steel or ceramic balls) are lifted to a certain height and then allowed to fall Ball Mill Grinding Machines: Working Principle, 2024年3月16日 A vertical coal mill is a type of industrial milling equipment used to crush and grind coal into powder for use in thermal power plants and the cement industry, featuring a vertical structure that facilitates efficient How Does a Vertical Coal Mill Work Coal

.png)

Coal Water Slurry Ball Mill

Coal water slurry ball mill (CWS ball mill) is the key equipment for coal water slurry fuel production, which is commonly used in coal water slurry power plant Coal water slurry ball mill is grinding equipment specially used for coal water 2023年10月7日 et al 2017) In a coalfired power plant, one of the main equipment is the coal mill, whose effectiveness influences mainly the whole power plant performance (Shah, An investigation of performance characteristics and A coal mill is used to grind and dry raw coal into fine powder, which is then burned to generate heat in the boiler to produce steam for power generation How does a coal ball mill work? A How does a Coal Mill Work? ball mills supplier2023年8月28日 Understanding Coal Mills in Thermal Power Plants: Coal mills are largescale industrial equipment designed to pulverize coal into fine particles suitable for combustion in Coal Mill in Thermal Power Plant: Enhancing Efficiency and

46.jpg)

What Is a Ball Mill? Understanding How It

2024年12月12日 How Does a Ball Mill Work? Capable of handling up to 384 samples, it’s ideal for highthroughput tasks like nucleic acid extraction and material preparation 5 This mill employs highspeed impact grinding for 2019年10月1日 It is believed that the line load on particles in rod mills helps to break hard materials (Gupta and Yan, 2016) By comparison, the point load on the particles in ball mills is Wet and dry grinding of coal in a laboratoryscale ball mill: Particle 2021年10月28日 From the coal yard, the coal is transfer to the mill bunkers through conveyor belt The bunkers are sized for an effective capacity of twelve (12) hours at BMCR with design Analysis of the Coal Milling Operations to the Boiler 2016年11月13日 The initial process in coal based thermal power plant is coal handlingThe Function of coal Handling Plant in thermal power plant is to receive , process, store, feed the Coal Handling Plant In Thermal Power

MRHS Mill Reject Handling System in Thermal

2021年5月20日 The function of Mill Reject Handling system (MRHS) is to automatically discharge the iron pyrite and other non‐grind‐able material from coal mill through an outlet connection to the reject conveying system Basic 2011年12月31日 Automation technologies can play a vital role in thermal power plants equipment maintenance, where coal bunker liner are critical parts in terms of functioning and safetyOperation and Maintenance of Coal Handling 2015年8月1日 Mill problems originate mainly due to poor controls or faults occurring within the milling system As discussed by GQ Fan and NW Rees [3], the control of mills remains very Review of control and fault diagnosis methods applied to coal mills 2019年11月7日 Comprehensive treatment,we should have a test on the 300 MV unit steel ball coal mill pulverizing systemAt the same time,analyze the main operating parameters before Optimization and transformation of 300MV units steel ball coal mill

Optimisation of coal mill systems, with fire and explosion

2024年10月31日 Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The 2015年4月24日 2 Ball mill consist of a hollow cylindrical shell rotating about its axis Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Ball mill PPT SlideShareThe most used coal mills in cement plants are airswept ball mills and vertical roller mills At present, most cement plants use coal as the main fuel in the clinker production process The standard coal consumed by the new dry Coal Mill in Cement Plant Vertical Roller Mill2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical An investigation of performance

.jpg)

Ball Mill In Cement Plant Cement Ball Mill

Years of cement production practice shows that cement particle gradation should be distributed continuously within a certain size range Generally speaking, the cement particles smaller than 32 μm are beneficial to reduce 2020年1月1日 According to data from the World Coal Association, coalfueled power plants currently provide 37% of the global electricity [1] In 2017, China's coalfired power generation Wet and dry grinding of coal in a laboratoryscale ball mill: Particle Download scientific diagram Working process of a Tubeball mill from publication: A new modelbased approach for power plant Tubeball mill condition monitoring and fault detection With the Working process of a Tubeball mill2015年4月10日 power plants maximum requirements of fuel is a coal The handling of this fuel is a great job To handle the fuel, ie, coal, each power station is equipped with a coal handling OPERATION AND MAINTENANCE OF CRUSHER HOUSE

sbm/sbm working principle of coal handling plant ball mill

Write better code with AI Code review Manage code changes

湖南机械

--立式严磨机

--修路用来自中国的矿石磨粉机修路用来自中国的矿石磨粉机修路用来自中国的矿石磨粉机

--水泥流程图怎么画啊

--重绕选粉机定子绕组要多少钱

--南京磨粉机

--时产150方重钙粉方解石雷蒙机

--石灰石碳酸钙磨粉机55KW

--小粉碎机配多大重钙机

--滑石研磨机哪个品牌好?标准圆石灰石锥矿石磨粉机

--重钙磨粉机雷蒙机电流

--立式粉碎机有什么特点

--粉磨机刚开始频率正常一会变慢

--每小时产80T石膏石头磨粉机

--锂辉石石灰石粉磨系统机

--方解石粉碎机构设计

--粉体工程

--FZB450粉碎机FZB450粉碎机FZB450粉碎机

--日产量来自中国的矿石磨粉机

--源头厂家山冠大型立磨立式辊磨机

--晋江市某工业磨粉机厂家水土保持方案

--增湿灰循环脱硫技术

--非煤矿山爆破后产生什么有害气体

--雷蒙磨用的刀头或磨辊

--生物岩石膏重钙粉研磨机

--中速环辊磨

--硅灰石灰石碳酸钙磨粉机

--黄红丹生石灰膨润土磨粉机

--上海安邦雷蒙磨

--湛江花岗岩加工

--